Classic Sweater Flat Knitting Machine

Steiger Classic Sweater Flat Knitting Machine, which is more intelligent, efficient and fast, it is made by Cixing in China. Intelligent running machine type, three systems, no waste yarn, motorized yarn feeder, indluding auto-oiling. New functions such as intarsia, plaiting. looping, fling weft lin......

Send Inquiry

Product Description

Steiger Classic Sweater Flat Knitting Machine, which is more intelligent, efficient and fast, it is made by Cixing in China. Intelligent running machine type, three systems, no waste yarn, motorized yarn feeder, indluding auto-oiling. New functions such as intarsia, plaiting. looping, fling weft lining, sewing, hollowing are added to develop fashion and trend.

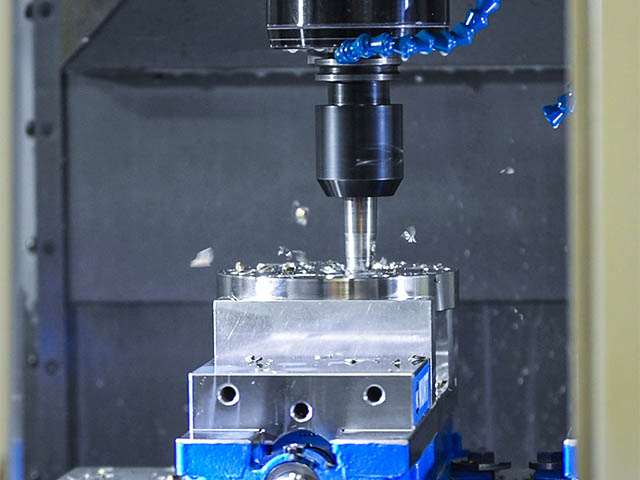

OEM Stainless Steel CNC Machining Factory.

"Control the standard by the details, show the power by quality". Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for High reputation China Youlin® Stainless Steel CNC Machining, We're seeking forward to receiving your enquiries quickly.

High reputation China Customized Stainless Steel CNC MachiningStainless Steel CNC Machining, Customized Machined Parts, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a ought to in your case personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We're confident that we are going to have a vibrant prospect and to be distributed all over the world in the years to come.

1.Stainless Steel CNC Machining Specialist

Precision Stainless Steel CNC Machining parts are becoming a choice for many industries due to its desirable physical properties! The below benefits have made Stainless Steel parts and products a viable choice for many industries and applications, though they are particularly favored in the medical, automotive, aerospace, healthcare and consumer electronics spheres. While the best and fastest way to make Stainless Steel parts is CNC machining especially CNC milling with stainless steel reach far and wide.

Precision Stainless Steel CNC Machining parts are becoming a choice for many industries due to its desirable physical properties! The below benefits have made Stainless Steel parts and products a viable choice for many industries and applications, though they are particularly favored in the medical, automotive, aerospace, healthcare and consumer electronics spheres. While the best and fastest way to make Stainless Steel parts is CNC machining especially CNC milling with stainless steel reach far and wide.

We are committed to providing high-quality services at competitive prices. Our broad experience combined with our expertise has helped us take up various complex projects with ease. Our long list of happy and satisfied customers is the testament of our commitment to provide quality services at fastest turnaround times. Contact us or request a quote today about utilizing our Youlin® stainless steel CNC Machining services.

2.Advantages of Stainless Steel CNC Machining

●Great precision and high tolerance ensure high-quality stainless steel parts

●Great precision and high tolerance ensure high-quality stainless steel parts

●Time and cost-saving, great speed of CNC Machining Stainless Steel part

●Allows products ordered to be made precisely to the specifications stated

●Complex stainless steel parts for high tech industry can be machined

3.Material Grade & Application of Stainless Steel CNC Machining

Stainless steels are high-alloy steels with superior corrosion resistance to carbon and low-alloy steels. This is largely due to their high chromium content, with most grades of stainless steel alloys containing at least 10% of the element.

Stainless steel can be broken out into one of five categories: Austenitic, Ferritic, Martensitic, Precipitation Hardened (PH), and Duplex. In each category, there is one basic, general purpose alloy. From there, small changes in composition are made to the base in order to create specific properties for various applications.

For reference, here are the properties of each of these groupings, as well as a few examples of the popular grades and their common uses.

CategoryPropertiesPopular GradesCommon Uses

AusteniticNon-magnetic, outstanding corrosion and heat resistance.304, 316Food processing equipment, gutters, bolts, nuts, and other fasteners.

FerriticMagnetic, lower corrosion and heat resistance than Austenitic.430, 446Automotive parts and kitchen appliances.

MartensiticMagnetic, moderate corrosion resistance – not for severe corrosion.416, 420, 440Knives, firearms, surgical instruments, and hand tools.

Precipitation Hardened (PH)Strongest grade, heat treatable, severe corrosion resistance.17-4 PH, 15-5 PHAerospace components.

DuplexStronger mixture of both Austenitic and Ferritic.244, 2304, 2507Water treatment plants, pressure vessels.