Why Are Steel Nuts So Important in Construction and Manufacturing?

2024-12-04

Steel nuts are a crucial component in many industrial and construction applications. From assembling machinery to building infrastructure, these small yet mighty fasteners are used to hold things together, ensuring stability and safety. But why are steel nuts so important? What makes them the go-to choice for engineers, builders, and manufacturers? Let’s dive into the reasons behind the widespread use of steel nuts and explore their significance in construction and manufacturing.

What Exactly Are Steel Nuts?

A steel nut is a type of fastener with a hexagonal or square shape, typically made of steel, that is designed to be threaded onto a bolt or a screw. The internal threads of the nut engage with the external threads of the bolt or screw, allowing the two parts to be securely joined together. Steel nuts come in various sizes, grades, and finishes, making them suitable for a wide range of applications where strong and reliable fastening is required.

Why Steel Nuts Are a Preferred Choice

1. Durability and Strength

One of the main reasons steel nuts are so popular is their strength and durability. Steel is a tough material that can withstand high levels of stress, pressure, and wear. In demanding applications such as construction, automotive, and heavy machinery, steel nuts are often the preferred choice because they offer exceptional tensile strength, which helps prevent loosening or breaking under heavy loads.

Furthermore, steel is highly resistant to corrosion, particularly when coated or alloyed with elements like zinc. This makes steel nuts suitable for use in harsh environments, such as outdoor construction sites, oil rigs, or machinery exposed to moisture.

2. Versatility

Steel nuts come in a variety of sizes, types, and grades, allowing them to be used in a wide range of applications. Whether you need a simple hex nut, a locking nut, or a flange nut, there’s a steel nut available that meets the specific needs of your project. From securing furniture to assembling heavy industrial equipment, steel nuts offer a versatile solution for virtually any fastening requirement.

The adaptability of steel nuts also makes them a key component in different industries, including automotive, aerospace, manufacturing, and even home improvement. Their ability to work in diverse conditions adds to their widespread appeal.

3. Cost-Effectiveness

Compared to other materials, steel is relatively inexpensive, making steel nuts a cost-effective solution for many applications. The affordability of steel allows manufacturers and construction companies to purchase these fasteners in bulk without breaking their budgets. Additionally, steel nuts often last longer than those made from weaker materials, which can lead to savings in maintenance and replacements over time.

4. Ease of Use

Steel nuts are easy to install, making them a go-to choice for builders and engineers who need to quickly and securely fasten components. With the right bolt or screw, steel nuts can be quickly threaded and tightened by hand or with tools, saving time on assembly. This ease of installation also makes them suitable for both professional applications and DIY projects.

5. Heat Resistance

Steel nuts, especially those made from high-carbon or stainless steel, have excellent resistance to high temperatures. This property makes them ideal for use in applications where heat buildup is a concern, such as in automotive engines or industrial machines. The ability to withstand high temperatures ensures that steel nuts remain intact and functional even in environments where other materials might weaken or fail.

The Different Types of Steel Nuts

1. Hex Nuts

Hex nuts are the most common type of steel nut. Their six-sided shape makes them easy to tighten with standard wrenches or spanners. They are used in a wide range of applications, from construction to home repairs.

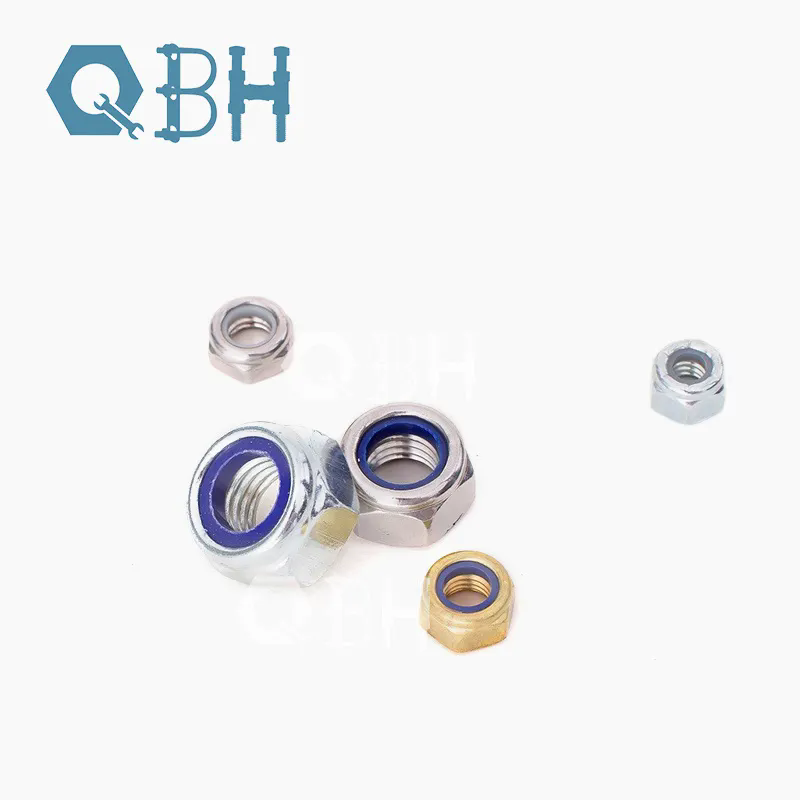

2. Lock Nuts

Lock nuts are designed to resist loosening due to vibrations or movement. They often feature a nylon insert or a serrated edge that helps grip the bolt or screw more tightly, preventing the nut from coming loose. Lock nuts are commonly used in machinery and automotive applications where vibrations are a concern.

3. Flange Nuts

Flange nuts have a built-in washer-like flange at the base, which helps distribute the load more evenly and prevent damage to the material being fastened. They are particularly useful when working with softer materials or in situations where extra stability is needed.

4. Wing Nuts

Wing nuts feature two "wings" that allow them to be tightened by hand without the need for tools. These nuts are often used in applications where frequent removal and installation are required, such as in temporary structures or equipment.

5. Cap Nuts

Cap nuts, also known as acorn nuts, are used to cover the exposed end of a bolt to prevent damage to the threads and provide a finished appearance. These nuts are commonly used in automotive or decorative applications.

How Steel Nuts Contribute to Safety

In construction and manufacturing, the safety of workers and end-users is always a top priority. Steel nuts contribute significantly to this safety in several ways:

- Structural Integrity: Steel nuts help maintain the structural integrity of buildings, machinery, and vehicles by keeping components securely fastened. Inadequate fastening can lead to catastrophic failures, such as machinery malfunctions, structural collapses, or vehicle accidents. Steel nuts provide the reliability needed to prevent these types of failures.

- Preventing Vibrations: Many industrial and automotive applications involve components that experience vibrations. Without proper fasteners, such as lock nuts, parts could become loose over time. Steel lock nuts, with their vibration-resistant features, help ensure that everything remains in place, even under constant movement.

- Corrosion Resistance: In outdoor or marine environments, steel nuts coated with corrosion-resistant materials like zinc help prevent rust and degradation, ensuring the safety and longevity of the fastenings.

Applications of Steel Nuts

Steel nuts are used in virtually every industry. Here are a few examples of how they are applied:

- Construction: Steel nuts are used to secure steel beams, structural components, and heavy machinery. They are essential in building bridges, skyscrapers, and other large structures that require high levels of stability.

- Automotive: Steel nuts are used throughout the automotive industry to secure parts such as engine components, exhaust systems, and wheels. Their durability and heat resistance make them essential for maintaining vehicle performance.

- Electronics: In electronic devices, steel nuts help secure components in place, ensuring that sensitive parts stay intact and that connections are stable.

- Home Improvement: Steel nuts are commonly used in DIY projects, such as furniture assembly, garden equipment repairs, and more. Their ease of use and reliability make them popular among hobbyists and homeowners.

Conclusion

Steel nuts are far more than just small fasteners—they are essential components in construction, manufacturing, and countless other industries. Their strength, durability, versatility, and affordability make them a preferred choice for securing components in a wide range of applications. Whether you’re working on a large construction project or fixing a household appliance, steel nuts provide the reliability needed to ensure safety and stability. Their ability to withstand pressure, heat, and vibrations makes them indispensable in today’s world of engineering and manufacturing.