What is PCB Fabrication and Why Is It Crucial for Electronics?

2024-12-04

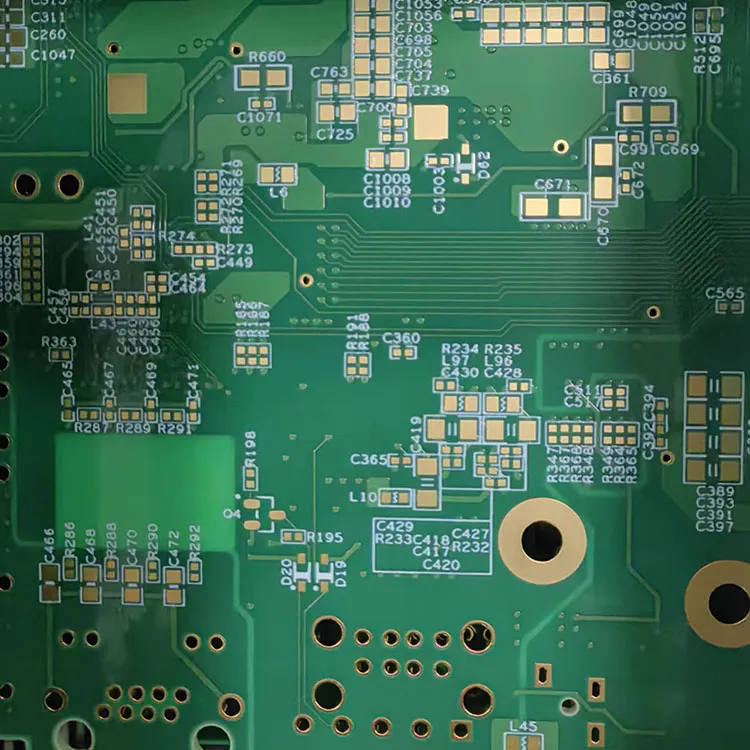

PCB (Printed Circuit Board) fabrication is the process of creating the physical board that connects and supports electronic components in almost every electronic device. From your smartphone to industrial machinery, PCBs play a pivotal role in the functionality of modern electronics. But what exactly is PCB fabrication, and why is it so essential in the world of electronics?

What Is PCB Fabrication?

PCB fabrication involves several steps that transform a design layout into a functional board that houses the circuitry of an electronic device. Essentially, it's the process of building a PCB from a flat sheet of material (usually fiberglass, copper, and other compounds), which will later serve as the foundation for mounting electrical components like resistors, capacitors, and integrated circuits.

The process begins with a detailed design created through software, which is then transferred onto the physical material. This design guides the routing of electrical pathways and placement of components. Once this is done, the board undergoes various stages like etching, drilling, plating, and testing to ensure it is ready for assembly.

Why Is PCB Fabrication Important?

1. Enabling Electronics Functionality

The primary purpose of PCB fabrication is to provide a structured platform for electronic components to function together. A PCB serves as the backbone that connects different parts of an electronic circuit, allowing signals and power to flow smoothly between components. Without PCBs, assembling circuits and making them work efficiently would be nearly impossible. Every modern gadget, from consumer electronics to automotive systems, relies on high-quality PCBs to perform complex tasks.

2. Miniaturization and Efficiency

PCB fabrication is key to the miniaturization of electronics. As technology advances, devices become smaller, more compact, and more powerful. Through PCB fabrication, it's possible to reduce the size of electronic systems while maintaining or improving their functionality. With techniques like multi-layer boards, small-pitch components, and advanced fabrication methods, PCBs allow electronic devices to have high-density circuitry in a small form factor, which is crucial for everything from mobile phones to medical devices.

3. Cost-Effective Production

One of the major benefits of PCB fabrication is its cost-effectiveness. The process enables the mass production of reliable and high-quality boards at scale. Once the initial design is complete, PCBs can be fabricated in bulk, allowing manufacturers to save on production costs. The use of automation and precision engineering also reduces errors and waste, further driving down costs. This scalability makes PCBs an affordable solution for manufacturers, whether they're producing simple electronics or complex, specialized equipment.

4. Customization for Specific Applications

PCB fabrication allows for the creation of custom boards suited to specific applications. Depending on the needs of the device, different types of PCBs can be fabricated, such as single-layer, double-layer, or multi-layer boards. More advanced designs include flexible PCBs, which are often used in wearables and other compact devices. The fabrication process also allows for integration with other materials or technologies, such as high-frequency circuits, making it possible to tailor each board for its intended function.

5. Ensuring Reliability and Performance

PCBs are designed to withstand various environmental factors, such as temperature fluctuations, moisture, and vibration. High-quality PCB fabrication ensures that the boards are durable, stable, and reliable over time. During the fabrication process, manufacturers conduct rigorous testing and quality control to verify that the boards meet strict standards. This testing ensures that the PCBs can operate reliably in their final applications, whether in consumer electronics or critical industrial machinery.

6. Support for Innovation in Electronics

PCB fabrication is not just about manufacturing; it's a driving force for innovation in the electronics industry. As new technologies emerge, PCB fabrication adapts to meet new challenges. From 5G devices and autonomous vehicles to wearable tech and IoT systems, PCBs continue to evolve, supporting more complex and integrated designs. With advancements in fabrication techniques, engineers are now able to push the boundaries of what electronics can do, creating devices that were once thought impossible.

The Process of PCB Fabrication

PCB fabrication involves several critical steps, which must be carefully executed to ensure that the final product functions as intended:

1. Design and Layout: The first step is designing the circuit layout using CAD software. This layout includes all components and their connections, ensuring that the PCB will perform the desired electrical functions.

2. Printing the Design: Once the design is complete, it's transferred onto a copper-clad laminate (usually fiberglass). This is typically done through a process called photolithography, where the design is etched onto the copper surface.

3. Etching: The unwanted copper is chemically etched away, leaving behind the desired circuit paths. This is crucial for ensuring that the PCB has the necessary electrical pathways.

4. Drilling and Plating: Holes are drilled into the PCB for component leads, and these holes are plated to allow for electrical connections between the layers of the PCB.

5. Assembly: After the fabrication of the PCB, it is sent for assembly, where electronic components are mounted onto the board. This includes everything from surface-mount devices (SMDs) to through-hole components, depending on the design.

6. Testing and Quality Control: Finally, the fabricated and assembled PCB is tested for functionality, ensuring that all connections are correct and that the board performs as expected.

Challenges in PCB Fabrication

While PCB fabrication has become a streamlined and efficient process, there are still several challenges that manufacturers face:

1. Design Complexity: As electronics become more sophisticated, the designs for PCBs grow increasingly complex. This requires highly skilled engineers and advanced design software to create layouts that are both functional and manufacturable.

2. Miniaturization: The trend toward smaller and more compact electronics puts pressure on PCB manufacturers to create boards with more components in a smaller space. This often leads to the need for smaller components and more precise manufacturing techniques.

3. Material Selection: Choosing the right materials for the PCB, including the base laminate and the copper used for the circuits, is crucial. The material must be suited to the device’s function, whether it’s heat resistance, signal speed, or flexibility.

4. Cost Management: Despite its cost-effectiveness, PCB fabrication can still be expensive for highly specialized or low-volume products. Manufacturers must balance cost with the need for quality and performance.

Conclusion

PCB fabrication is an integral part of the electronics manufacturing process, supporting everything from simple gadgets to highly complex machinery. It allows for the production of high-quality, reliable, and cost-effective circuit boards that are essential for modern technology. As the electronics industry continues to evolve, the importance of PCB fabrication will only grow, driving innovation and enabling new advancements in technology. Whether you're working on a consumer product or an industrial application, understanding PCB fabrication is key to appreciating the role it plays in making modern electronics possible.