Streamlining Production with Stripping Dies Auto Bending Machines

2024-08-10

In the fast-paced world of manufacturing, efficiency and precision are paramount. Stripping dies auto bending machines have become indispensable tools in various industries, offering a blend of automation, accuracy, and flexibility. This blog delves into the functionality, advantages, and applications of stripping dies auto bending machines, highlighting their role in revolutionizing production processes.

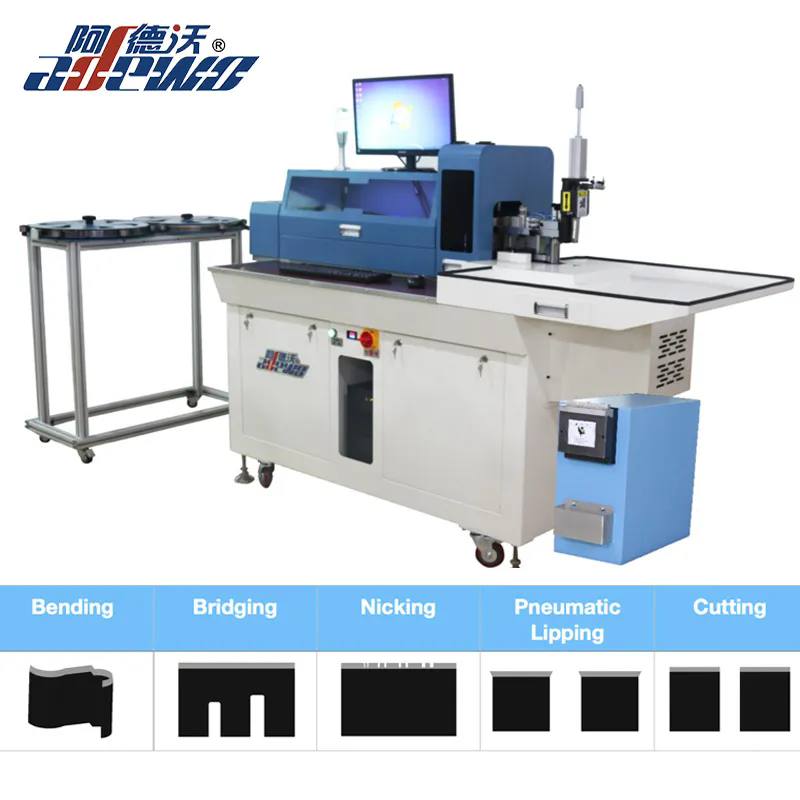

What Are Stripping Dies Auto Bending Machines?

Stripping dies auto bending machines are specialized equipment used in the manufacturing of metal components, primarily for the electronics, automotive, and aerospace industries. These machines integrate two crucial processes: stripping and bending.

1. Stripping Dies: These are used to remove excess material or trim metal parts from a strip or sheet. Stripping dies ensure that the parts are precisely cut to the required shape and size, ready for further processing.

2. Auto Bending: This process involves bending metal strips into specific angles and shapes as required by the design specifications. Auto bending machines automate this process, allowing for consistent and precise bends.

Key Features of Stripping Dies Auto Bending Machines

1. High Precision and Consistency

- Accurate Cuts and Bends: These machines are engineered to deliver high precision in both stripping and bending operations. Advanced controls and automation ensure that each part meets strict tolerances and specifications.

- Reduced Variability: Automation reduces the risk of human error, leading to consistent quality and uniformity in the final products.

2. Enhanced Efficiency

- Speed: Automated processes significantly increase production speeds compared to manual operations. This efficiency is crucial for meeting high-volume production demands.

- Reduced Downtime: Automated systems often include features like quick tool changes and minimal setup times, reducing overall machine downtime.

3. Flexibility and Versatility

- Adjustable Settings: Modern stripping dies auto bending machines offer adjustable settings for different material types, thicknesses, and bending angles, allowing for a wide range of applications.

- Multi-Functionality: Some machines combine additional processes, such as punching or forming, further enhancing their versatility in manufacturing.

4. Advanced Control Systems

- Computer Numerical Control (CNC): Many auto bending machines are equipped with CNC systems, enabling precise control over the bending process and facilitating complex geometries.

- Programmable Functions: Operators can program and store various bending profiles and stripping configurations, making it easier to switch between different production runs.

Benefits of Using Stripping Dies Auto Bending Machines

1. Improved Production Quality

- Consistency: Automation ensures that every part is produced to the same high standards, minimizing defects and variability.

- Accuracy: Precision in stripping and bending reduces the need for rework or adjustments, leading to better overall product quality.

2. Increased Production Speed

- Efficiency: The ability to process large quantities of parts quickly helps meet production deadlines and increases throughput.

- Automation: Automated operations reduce the time spent on manual tasks, allowing for faster production cycles.

3. Cost-Effectiveness

- Labor Savings: Reduced reliance on manual labor lowers operational costs and can lead to significant savings over time.

- Material Optimization: Precise stripping and bending reduce material waste, further contributing to cost savings.

4. Enhanced Safety

- Reduced Manual Handling: Automation minimizes the need for manual handling of sharp or heavy metal parts, improving workplace safety.

- Safety Features: Many machines are equipped with safety guards and sensors to protect operators and prevent accidents.

Applications of Stripping Dies Auto Bending Machines

1. Electronics Industry

- PCB Manufacturing: These machines are used to produce components for printed circuit boards (PCBs), where precision and consistency are critical for functionality and performance.

- Connectors and Contacts: Stripping dies and auto bending are essential for manufacturing electrical connectors and contacts used in various electronic devices.

2. Automotive Industry

- Metal Brackets and Clips: Auto bending machines are used to produce metal brackets, clips, and other components required in automotive assembly and manufacturing.

- Chassis Components: Precision bending and stripping are crucial for producing chassis parts and structural components.

3. Aerospace Industry

- Structural Parts: Aerospace components often require complex geometries and high precision, making auto bending machines vital for manufacturing structural and support parts.

- Engine Components: The ability to handle high-strength materials and maintain accuracy is essential for producing engine components and other critical parts.

4. Consumer Goods

- Household Appliances: Stripping dies auto bending machines are used to manufacture parts for household appliances, such as metal brackets and components for assembly.

- Furniture: The machines can also be employed in the production of metal components for furniture, offering precision and efficiency in manufacturing.

Choosing the Right Stripping Dies Auto Bending Machine

1. Assess Production Needs

- Volume and Speed: Determine the production volume and speed requirements to select a machine that meets your operational needs.

- Material Types: Ensure the machine can handle the types and thicknesses of materials you use.

2. Evaluate Features

- Control Systems: Look for machines with advanced CNC controls and programmable functions for greater flexibility and precision.

- Additional Functions: Consider machines that offer additional features, such as punching or forming, if needed for your production processes.

3. Consider Maintenance and Support

- Service and Support: Choose a machine from a reputable manufacturer that offers reliable service and support.

- Maintenance Requirements: Evaluate the maintenance needs and ensure that the machine is easy to maintain and repair.

Conclusion

Stripping dies auto bending machines represent a significant advancement in manufacturing technology, combining automation, precision, and efficiency to enhance production processes. Their ability to streamline stripping and bending operations makes them invaluable in industries such as electronics, automotive, aerospace, and consumer goods.

By understanding the features, benefits, and applications of stripping dies auto bending machines, manufacturers can make informed decisions that drive productivity, quality, and cost-effectiveness. Embrace the power of automation and precision with these innovative machines to transform your production capabilities and stay ahead in the competitive manufacturing landscape.