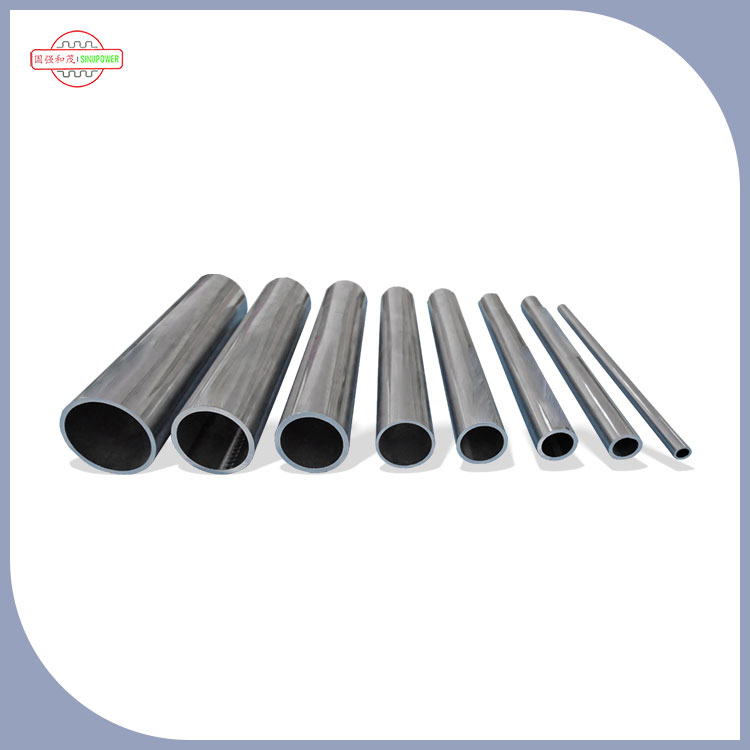

Round Condenser Tube: Essential Component in Heat Exchange Systems

2025-04-16

In various industrial applications, the efficient exchange of heat is vital for maintaining operational efficiency and product quality. One of the key components in heat exchange systems is the round condenser tube, a crucial element in processes such as refrigeration, power generation, and chemical processing. These tubes are integral to systems where heat needs to be removed from a substance to allow for cooling or condensation.

In this blog, we’ll explore what a round condenser tube is, how it works, and the industries that rely on it for maintaining temperature control and process optimization.

What is a Round Condenser Tube?

A round condenser tube is a cylindrical tube used in heat exchangers to facilitate the transfer of heat from a hot fluid to a cooling medium, typically water or air. Condenser tubes are a vital part of the cooling system in industries where the condensation of vapor is required. The round shape of the tube maximizes the surface area for heat exchange, improving efficiency and ensuring that the cooling or condensation process occurs effectively.

These tubes are commonly made from materials like copper, stainless steel, or aluminum, which have high thermal conductivity, allowing them to quickly absorb heat from the fluid passing through them. The round design also ensures that the fluid flows in a manner that minimizes turbulence, optimizing the heat exchange process.

How Does a Round Condenser Tube Work?

The basic principle behind the functioning of a round condenser tube involves transferring heat from the hot fluid inside the tube to the cooler surroundings, such as water or air. Here’s a breakdown of how this process works:

1. Fluid Flow: The hot fluid (often vapor) enters the tube, which is typically heated by a process like steam generation or chemical reactions. As the fluid moves through the tube, it releases heat to the walls of the tube.

2. Heat Transfer: The heat from the fluid is transferred to the surface of the tube. In many cases, the tube is surrounded by a cooler substance—usually water or air—that is used to absorb the heat.

3. Condensation: As the hot fluid cools down, it condenses into a liquid. This condensation process occurs because the temperature of the fluid drops below its boiling point, and it changes from a gas or vapor phase to a liquid phase.

4. Cooling Medium: The cooling medium (water or air) surrounding the tube absorbs the heat, lowering the temperature of the fluid inside the tube and causing condensation. This cooled fluid can then be recirculated back into the system or further processed.

The round condenser tube allows for efficient heat transfer due to its large surface area, which enhances the heat exchange between the fluid and the surrounding environment.

Materials Used for Round Condenser Tubes

The materials used to manufacture round condenser tubes are essential in ensuring their durability, efficiency, and resistance to corrosion and scaling. Here are some common materials used:

- Copper: Copper is a popular material for condenser tubes because of its excellent thermal conductivity, which helps in transferring heat efficiently. It is also highly resistant to corrosion, making it ideal for use in systems that deal with moisture or water.

- Stainless Steel: Stainless steel is often chosen for condenser tubes due to its strength, resistance to corrosion, and durability. It is commonly used in harsh chemical environments where other metals might corrode quickly.

- Aluminum: Aluminum is another material used in round condenser tubes, particularly in systems where weight and cost are important considerations. Although it has lower thermal conductivity than copper, it is still effective in many cooling applications and is lightweight, which makes it easier to handle.

The choice of material typically depends on the specific requirements of the system, such as the type of fluid being processed, temperature ranges, and the environmental conditions of the system.

Benefits of Round Condenser Tubes

1. Efficient Heat Transfer

The round shape of the condenser tube maximizes the surface area for heat exchange. This results in efficient cooling and condensation, which is crucial in industries that require precise temperature control.

2. Durability and Longevity

Condenser tubes are designed to withstand high temperatures and pressures, especially in industrial applications. Materials like copper and stainless steel ensure that the tubes remain functional for a long period, even under harsh conditions.

3. Compact Design

The round design of the tube allows for a compact setup that can fit into a variety of heat exchange systems. This makes it easier to integrate into existing systems without requiring significant space or modifications.

4. Corrosion Resistance

With the right materials, such as copper or stainless steel, round condenser tubes are highly resistant to corrosion and scaling. This is essential in preventing the buildup of debris that could reduce the effectiveness of the system.

5. Energy Efficiency

The efficient heat transfer properties of round condenser tubes lead to improved energy usage in cooling systems. By effectively condensing vapor into liquid form, these tubes help optimize the energy required for cooling, making the process more cost-effective and sustainable.

Applications of Round Condenser Tubes

1. Refrigeration and Air Conditioning

Round condenser tubes are commonly used in refrigeration and air conditioning systems to cool refrigerant gases. In these systems, the condenser tube helps remove heat from the refrigerant, enabling the cooling process to continue efficiently.

2. Power Plants

In power plants, especially those that use steam turbines, round condenser tubes are used to cool the steam after it passes through the turbine. The condensed steam is then returned to the boiler to be reheated, creating a closed-loop system.

3. Chemical Processing

In the chemical industry, round condenser tubes are used in processes like distillation, where heat needs to be removed from vaporized chemicals. The condenser tubes help condense the vapor back into liquid form, enabling further processing and separation of components.

4. Petrochemical Industry

In the petrochemical industry, condenser tubes play a crucial role in distillation columns, cooling down the gases and separating them into different components based on their boiling points. These tubes help improve the efficiency of refining processes.

5. Food and Beverage Industry

Round condenser tubes are also used in the food and beverage industry to cool down liquids such as juices or to maintain optimal temperatures in food processing operations. The efficient heat exchange provided by the tubes helps preserve the quality and taste of the products.

Conclusion

Round condenser tubes are vital components in many heat exchange systems, playing an essential role in cooling, condensation, and temperature regulation across a range of industries. Their efficient heat transfer capabilities, durability, and adaptability make them indispensable in applications such as refrigeration, power generation, chemical processing, and more.

By ensuring that heat is effectively transferred and fluids are condensed, these tubes help maintain the integrity of products, conserve energy, and improve overall system performance. Whether you're looking to optimize a large-scale industrial system or streamline a smaller, more specific process, round condenser tubes provide the reliability and efficiency required for success.