Functions of Bearing Bushes in Pumps

2024-06-13

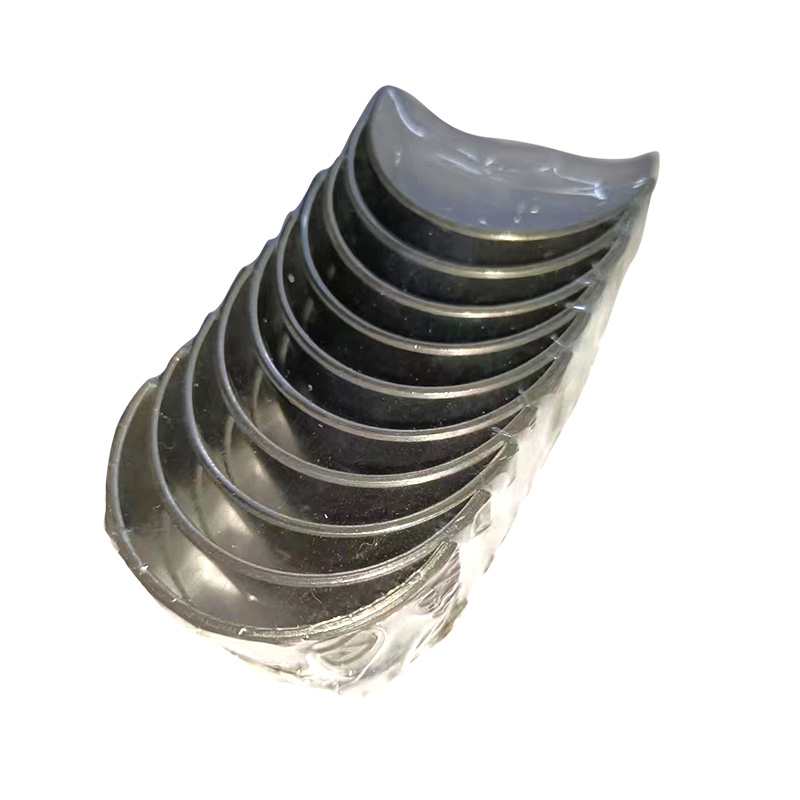

A bearing bush for a pump is a critical component designed to support the shaft and reduce friction within the pump assembly. It plays a crucial role in ensuring smooth operation, minimizing wear and extending the lifespan of the pump. Here’s an overview of the bearing bush for pumps, including its functions, materials used, manufacturing process, and considerations:

Functions of Bearing Bushes in Pumps

1. Support and Alignment: Provides support to the pump shaft, maintaining proper alignment within the pump casing.

2. Friction Reduction: Reduces friction between the rotating shaft and stationary parts, such as the pump casing or housing.

3. Load Bearing: Absorbs radial and axial loads generated by the shaft rotation and hydraulic forces.

4. Vibration Damping: Helps dampen vibrations caused by the rotating shaft, contributing to smoother operation and reduced noise levels.

Materials Used for Bearing Bushes

1. Bronze: Commonly used due to its excellent wear resistance, compatibility with various lubricants, and corrosion resistance.

2. Babbitt Metal: A soft alloy often used as a lining material to reduce friction and provide a smooth bearing surface.

3. Polymer Composites: Offer advantages such as self-lubrication, low friction, and resistance to chemicals and wear.

4. Steel: Sometimes used for specialized applications where high load capacity and strength are required.

Manufacturing Process

1. Casting: Bronze or other metal alloys are melted and poured into molds to form the bearing bush.

2. Machining: After casting, the bearing bush undergoes machining processes such as turning, milling, and grinding to achieve precise dimensions and surface finish.

3. Babbitt Lining: If using Babbitt metal, the bearing bush is coated or lined with Babbitt alloy through a bonding or centrifugal casting process.

4. Finishing: Final finishing processes include polishing and inspection to ensure the bearing bush meets specified tolerances and quality standards.

Considerations for Bearing Bushes in Pumps

1. Load Capacity: Select the bearing bush material and design capable of handling the radial and axial loads generated by the pump shaft.

2. Temperature and Environment: Consider the operating temperature range and exposure to chemicals or abrasive fluids to ensure material compatibility and longevity.

3. Lubrication: Ensure proper lubrication to minimize wear and reduce friction between the shaft and bearing surface.

4. Dimensional Accuracy: Precision machining and quality control are crucial to maintain dimensional accuracy and ensure proper fit within the pump assembly.

5. Maintenance: Periodic inspection and maintenance of bearing bushes are essential to detect wear, lubrication issues, or damage early and prevent pump failure.

Applications of Bearing Bushes in Pumps

1. Centrifugal Pumps: Used in various industrial applications for fluid transfer and circulation.

2. Positive Displacement Pumps: Includes gear pumps, diaphragm pumps, and piston pumps where precise fluid handling is critical.

3. Submersible Pumps: Found in applications such as wastewater management, drainage systems, and groundwater pumping.

4. Process Pumps: Used in chemical processing, oil and gas industries, and other specialized applications requiring reliable fluid handling.

Benefits of High-Quality Bearing Bushes

1. Extended Service Life: Reduces wear on pump components, leading to longer intervals between maintenance and replacement.

2. Reliability: Ensures smooth and efficient pump operation, minimizing downtime and improving overall system reliability.

3. Cost-Effectiveness: Reduces operating costs by lowering maintenance frequency and extending the lifespan of the pump assembly.

4. Performance: Enhances pump performance by maintaining proper shaft alignment, reducing vibration, and optimizing energy efficiency.

Summary

A bearing bush for a pump is a critical component that supports the shaft, reduces friction, and enhances the overall performance and reliability of the pump assembly. By choosing the right material, ensuring proper manufacturing processes, and considering operational factors, manufacturers can achieve efficient fluid handling and prolonged service life of pumps in various industrial and commercial applications.