Features of Anti-Static Acrylic Sheets

2024-06-20

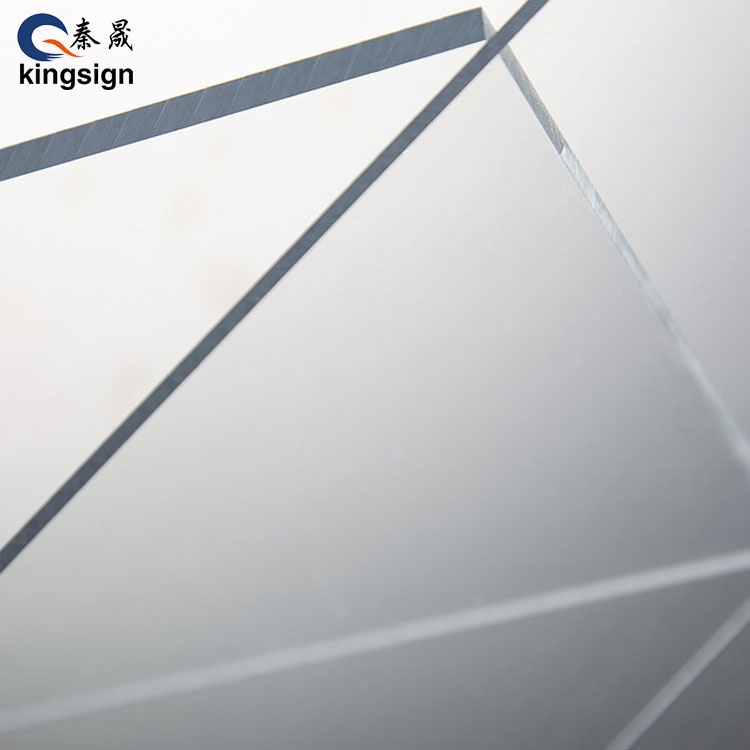

An anti-static acrylic sheet is a specialized type of acrylic material that has been modified to reduce or eliminate static electricity buildup on its surface. This property makes it particularly useful in applications where static electricity can interfere with operations or pose risks to sensitive electronic equipment. Here’s an overview of anti-static acrylic sheets, including their features, applications, benefits, and considerations:

Features of Anti-Static Acrylic Sheets:

1. Static Dissipation:

- Surface Treatment: Contains additives or coatings that facilitate the dissipation of static electricity.

- Conductive Properties: Designed to minimize the generation of static charges and quickly dissipate any accumulated static.

2. Material Properties:

- Acrylic Base: Maintains the optical clarity, durability, and weather resistance characteristic of standard acrylic sheets.

- Lightweight: Similar to regular acrylic, making it easy to handle and fabricate.

3. Surface Characteristics:

- Smooth Finish: Provides a smooth and uniform surface for applications where optical clarity is important.

- Cleanability: Easy to clean and maintain, suitable for environments requiring regular sanitation.

Applications of Anti-Static Acrylic Sheets:

1. Electronics and Semiconductor Industries:

- Clean Room Environments: Used in manufacturing facilities and clean rooms to prevent static charge accumulation that could damage sensitive electronic components.

- Test Equipment: Shields and enclosures for devices that require protection from electrostatic discharge (ESD).

2. Medical and Laboratory Equipment:

- Equipment Windows: Transparent shielding for medical devices, analytical instruments, and laboratory equipment to maintain sterile environments and protect sensitive samples.

3. Display Cases and Enclosures:

- Museum Displays: Used to showcase artifacts and exhibits without static buildup that could attract dust or damage delicate items.

- Retail Displays: Provides static control to protect electronic displays and interactive kiosks from static-related issues.

4. Personal Protective Equipment (PPE):

- Face Shields: Anti-static acrylic sheets can be used in face shields and protective barriers to reduce fogging and maintain visibility.

5. Industrial Applications:

- Machine Guards: Used as protective barriers around machinery and equipment in manufacturing facilities to prevent static discharge that could ignite flammable materials.

- Workstation Partitions: Static-safe partitions between workstations in electronics assembly and testing environments.

Benefits of Anti-Static Acrylic Sheets:

- Static Control: Prevents static charge buildup, reducing the risk of electrostatic discharge (ESD) and associated damage.

- Durability: Retains the impact resistance and weatherability characteristics of standard acrylic, suitable for both indoor and outdoor applications.

- Optical Clarity: Maintains transparency and light transmission, crucial for applications requiring clear visibility.

- Versatility: Can be cut, drilled, and shaped using standard acrylic fabrication techniques, offering flexibility in design and installation.

Considerations:

- Surface Maintenance: Anti-static properties may diminish over time with wear or cleaning, requiring periodic evaluation or reapplication of treatments.

- Compatibility: Ensure compatibility with specific cleaning agents and disinfectants used in the application environment to avoid damage to the material or reduction in anti-static effectiveness.

- Cost: Anti-static acrylic sheets may be more expensive than standard acrylic due to added manufacturing processes and materials.

Conclusion:

Anti-static acrylic sheets provide a valuable solution for controlling static electricity in various applications, ranging from electronics manufacturing and clean room environments to museum displays and medical equipment. By incorporating these sheets, industries can mitigate the risks associated with static discharge, ensuring the reliable operation and longevity of sensitive equipment and environments. Understanding their properties, applications, benefits, and maintenance considerations helps in selecting and utilizing anti-static acrylic sheets effectively for specific static-sensitive applications.