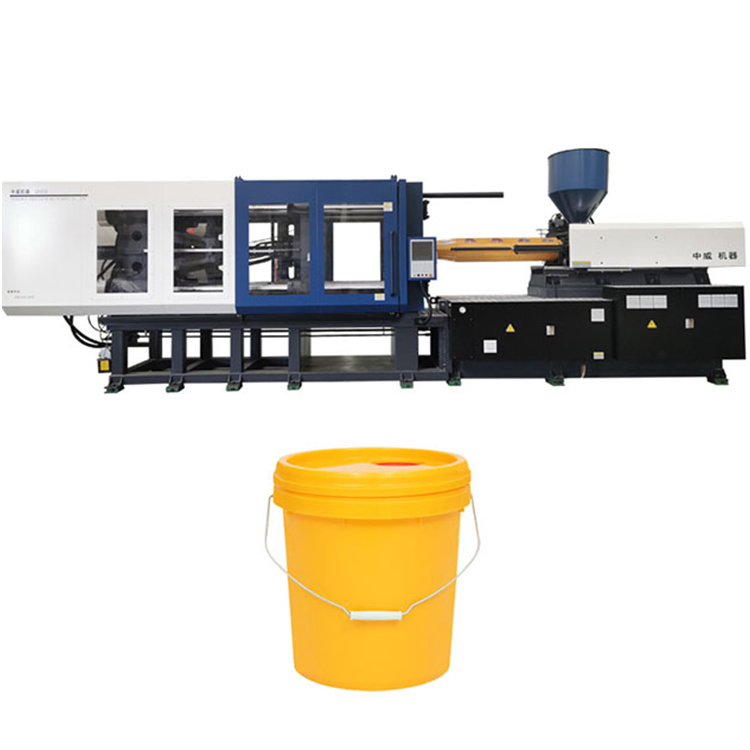

Features of an IML plastic bucket injection molding machine

2024-02-22

In-Mold Labeling (IML) is a technique used in injection molding where a label or graphic is placed in the mold before the plastic is injected. The label becomes an integral part of the molded product. An IML plastic bucket injection molding machine is specifically designed to incorporate this process in the production of plastic buckets.

Here are some key features and aspects of an IML plastic bucket injection molding machine:

1. IML System:

- The machine is equipped with an In-Mold Labeling system, which typically includes a label magazine, label pick-and-place system, and a mechanism for placing the label inside the mold before injection.

2. Injection Molding Process:

- Similar to conventional injection molding machines, an IML plastic bucket injection molding machine follows the standard injection molding process. This includes melting plastic pellets, injecting molten material into the mold, and cooling to solidify the plastic.

3. IML Label Handling:

- The IML system integrated into the machine handles the in-mold labels with precision. Labels are picked from the magazine and accurately placed in the mold cavities.

4. Mold Design:

- The mold used in the machine is designed to accommodate both the plastic bucket shape and the placement of the in-mold label. It consists of two halves - the cavity side, which shapes the bucket and embeds the label, and the core side.

5. Label Positioning:

- Precise label positioning is crucial for achieving high-quality IML plastic buckets. The machine ensures accurate placement of labels in the mold for each cycle.

6. Material Handling:

- The machine includes a material handling system for feeding plastic pellets into the machine's hopper. The plastic material used for the bucket and the label must be compatible.

7. Automation and Control:

- Modern IML plastic bucket injection molding machines often come with advanced automation features and computerized controls. These features allow for precise control of injection parameters, IML system operation, and other variables.

8. Cooling System:

- A cooling system is essential to ensure that both the plastic material and the in-mold label solidify correctly and maintain their structural integrity.

9. Ejection System:

- After the plastic has solidified in the mold, an ejection system is used to release the molded plastic bucket, now with the integrated label, from the mold.

10. Quality Assurance:

- The machine is designed to ensure high-quality production, meeting the specifications of both the plastic bucket and the in-mold label.

IML plastic bucket injection molding machines are commonly used in the packaging industry to produce containers with high-quality graphics and labeling. The IML process offers advantages such as enhanced aesthetics, durability of labeling, and efficient production of labeled products. Manufacturers can adjust the design and specifications of the machine based on the specific requirements of the plastic bucket and label design.