Features associated with a vibrating sieve stone washer

2023-11-15

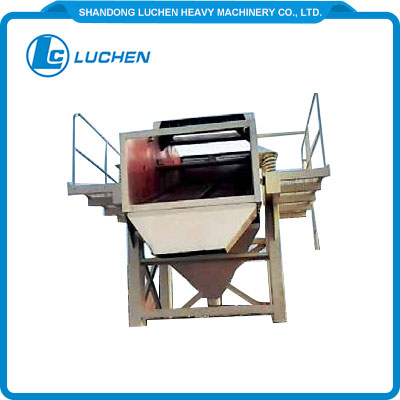

A vibrating sieve stone washer is a type of equipment used in the mining and aggregates industry for the classification and cleaning of crushed stone, gravel, and other materials. It combines the principles of vibration and water flow to separate and wash different-sized particles, removing impurities and ensuring a cleaner final product. Here are the key components and features associated with a vibrating sieve stone washer:

1. Vibrating Sieve:

- The vibrating sieve, often referred to as a vibrating screen or deck, is a meshed surface that vibrates to classify and separate particles based on their size. The sieve can have multiple layers with different-sized openings to achieve various levels of classification.

2. Vibration Mechanism:

- The vibration mechanism is responsible for imparting vibratory motion to the sieve. This can be achieved using eccentric weights, unbalanced shafts, or other mechanisms that generate controlled vibrations.

3. Water Spray System:

- A water spray system is integrated into the vibrating sieve stone washer to introduce water onto the material being processed. This water helps in the washing and cleaning process, removing fines and impurities.

4. Stone Washer:

- The stone washer component involves the use of water to wash and clean the crushed stone or gravel. It is typically a rotating drum or conveyor system through which the material passes, allowing the washing process to take place.

5. Inlet Hopper:

- An inlet hopper is where the raw material is fed into the vibrating sieve stone washer. It ensures a controlled and consistent flow of material onto the sieve.

6. Discharge Chute:

- The discharge chute allows the classified and cleaned material to exit the vibrating sieve stone washer. It may lead to further processing equipment or be directed to stockpiles.

7. Adjustable Settings:

- The equipment often comes with adjustable settings for vibration intensity, water flow rate, and other parameters. These settings allow operators to optimize the process for different types of materials and production requirements.

8. Dewatering Screen (Optional):

- In some configurations, a dewatering screen may be incorporated after the vibrating sieve stone washer to remove excess water from the material before it is discharged.

9. Support Structure:

- The vibrating sieve stone washer is mounted on a sturdy support structure to ensure stability during operation.

The vibrating sieve stone washer is commonly used in applications where the removal of fines, silt, and impurities from crushed stone or gravel is essential. This process is particularly important in producing high-quality aggregates for use in construction and concrete production. The combination of vibration and water washing helps achieve efficient classification and cleaning, resulting in a cleaner and more marketable product.