Detailed Overview of Guar Gum

2024-07-31

Guar gum is a natural polysaccharide derived from the seeds of the guar plant (*Cyamopsis tetragonoloba*), which is native to India and Pakistan. It is commonly used as a thickening, stabilizing, and gelling agent in various industries, including food, pharmaceuticals, and cosmetics. Here’s a detailed overview of guar gum:

Key Features

1. Chemical Composition:

- Polysaccharide: Guar gum is composed of galactose and mannose units, which form a high-molecular-weight polymer.

- Solubility: It is soluble in water and forms a gel-like consistency when dissolved.

2. Physical Properties:

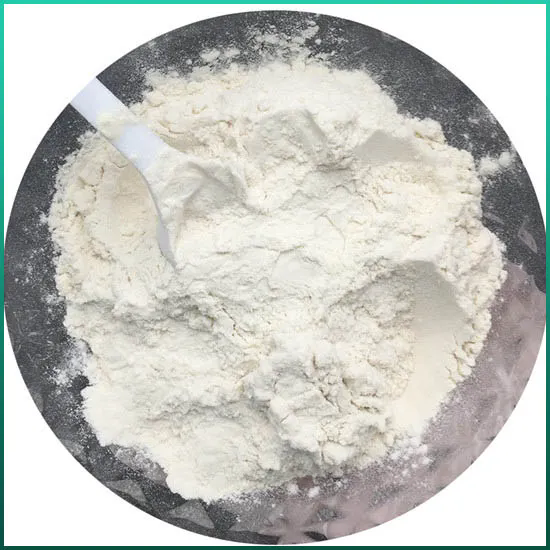

- Powder Form: Typically available as a fine, white to off-white powder.

- Viscosity: Has high viscosity even at low concentrations, which makes it effective as a thickening agent.

3. Applications:

- Food Industry: Used as a thickener, stabilizer, and emulsifier in products like sauces, soups, dressings, dairy products, and baked goods.

- Pharmaceuticals: Employed as a binder and disintegrant in tablets and as a thickening agent in liquid formulations.

- Cosmetics and Personal Care: Used in lotions, creams, and shampoos for its thickening and stabilizing properties.

- Industrial Uses: Utilized in oil drilling, textile printing, and paper manufacturing as a viscosifier and stabilizer.

Benefits

1. Thickening and Stabilizing:

- Effective Thickener: Provides excellent thickening properties, which is useful in various formulations.

- Stabilizing Agent: Helps to stabilize emulsions and suspensions, preventing the separation of ingredients.

2. Natural and Safe:

- Natural Source: Derived from the guar plant, it is a natural and generally recognized as safe (GRAS) ingredient.

- Non-Toxic: Non-toxic and safe for use in food and cosmetic products when used according to recommended guidelines.

3. Versatility:

- Wide Range of Applications: Suitable for use in diverse industries due to its thickening, gelling, and stabilizing properties.

4. Low Dosage Requirement:

- Efficient Use: Effective at low concentrations, making it cost-effective and efficient in various applications.

Considerations

1. Solubility and Mixing:

- Dissolution: Guar gum should be properly dissolved in water to avoid clumping. It is often best to disperse it in a small amount of water before adding it to a larger batch.

2. Temperature Sensitivity:

- Heat Stability: While generally stable, excessive heat can affect the viscosity and performance of guar gum. It is important to manage processing temperatures carefully.

3. Allergies and Sensitivities:

- Potential Allergens: Although rare, some individuals may have sensitivities or allergies to guar gum. It is important to monitor for any adverse reactions, especially in food products.

4. Regulatory Compliance:

- Usage Limits: Follow regulatory guidelines and recommendations for the appropriate use levels in different applications, particularly in food and pharmaceuticals.

Applications in Different Industries

1. Food Industry:

- Textural Improvement: Used in sauces, dressings, soups, and baked goods to improve texture and consistency.

- Fat Replacement: Can be used to mimic the texture of fat in reduced-fat products.

2. Pharmaceuticals:

- Tablet Formulation: Acts as a binder and disintegrant in tablets, aiding in controlled release and dissolution.

3. Cosmetics and Personal Care:

- Emulsion Stabilization: Enhances the stability and consistency of lotions, creams, and shampoos.

4. Industrial Applications:

- Oil Drilling: Used as a viscosifier in hydraulic fracturing fluids.

- Textile Printing: Serves as a thickening agent in textile dyes and prints.

Guar gum is a versatile and effective ingredient used in a variety of applications for its thickening, stabilizing, and gelling properties. Understanding its characteristics and applications helps in utilizing it effectively across different industries.